News & Events

Articles

Surviving Cold Weather

Choosing the Right Regulator(s) for an LP Gas System

The Case for Propane Autogas

Winter is coming and although we may want to hope for the best, it's usually better to plan for the worst. In an effort to assist you with your preparation process, we provide items intended to enable you, and your customers, to better survive cold weather.

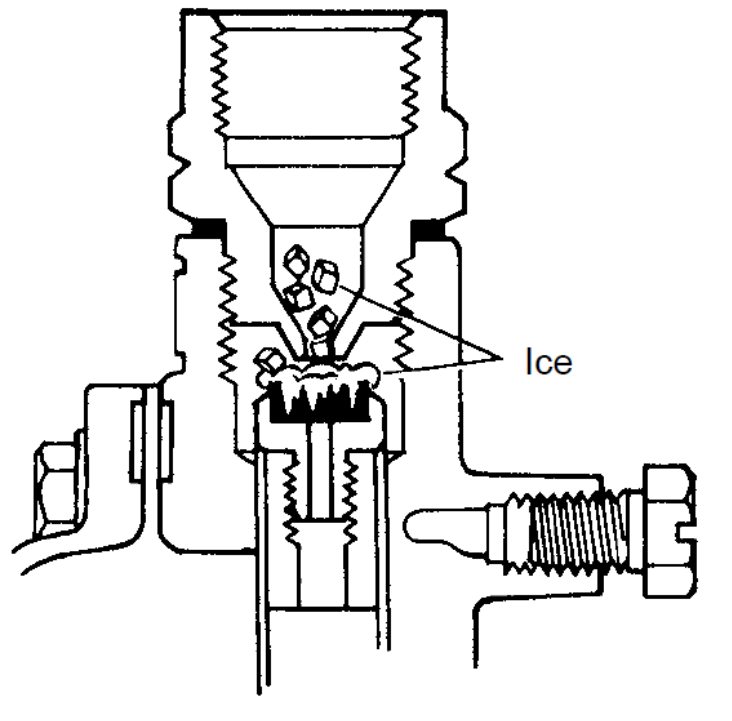

Regulator freeze-ups occur because there is excessive moisture in propane, or when the flow of propane is restricted due to pigtails that are improperly formed or kinked. Temperature may also be a contributing factor… freeze-ups can even occur at temperatures above 32° Fahrenheit.

Propane should be checked for moisture content prior to delivery to consumers.

Install RegO 5 PSI First Stage Regulators (SR9 type) when the temperature drops to a certain point, there won’t be enough pressure for a 10 PSI regulator to operate.

Example: 1,000,000 BTU load at 5 PSI

1,000,000 x 1.120 = 1,120,000 BTUs… then use chart based on 1,120,000

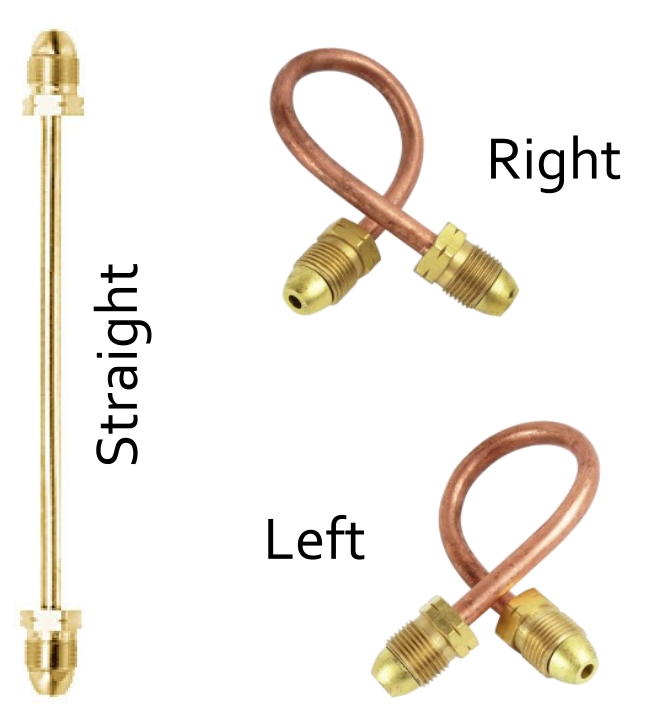

Use 3/8” tube, heavy-duty RegO Hog Tails. They’re available in a variety of connections, lengths and styles (straight or preformed). They have individually soldered connections to the copper tubing and are tested prior to shipment.

Notes:

1. RegO recommends that a new pigtail or hog tail be installed with every new or replacement regulator.

2. Care should always be taken in selecting the proper pigtail for each application.

A Viatran AT-1000 Freeze Valve indicates the presence, or absence, of moisture in liquefied propane gas (LPG).

The use of this valve, and test method, provides a relative measure of the tendency of liquefied petroleum gasses containing moisture to freeze in pressure-reducing regulators which may interrupt the normal flow of gas.

Any container suspected of having excessive moisture should be treated with the proper amount of methanol. A gravity-fed Methanol Injector, with 1-1/4” ACME connector (female), provides a fast and efficient method to inject methanol into stationary ASME containers to help prevent condensation from freezing in the propane system.

Interested in saving this article?

Choosing the Right Regulator(s) for an LP Gas System

Selecting the correct regulator for an LP Gas system is essential for ensuring safety, efficiency, and optimal performance. Whether you’re installing a residential system or managing a commercial application, understanding the types of regulators and their specific uses will enable you to make the best choice for your systems. The guide below is intended to assist you with the process of selecting the right regulator for various applications.

The Important Role of Regulators

Regulators play a vital role in both safety and the efficient use of propane systems by consistently controlling pressure of propane gas flowing from a tank to appliances. A properly functioning regulator maintains stable pressure and prevents fluctuations which could otherwise lead to inefficient appliance performance, energy waste, or, in extreme cases, hazardous conditions such as leaks or fires.

Types of Regulators

Different applications require specific types of regulators. Here are the most common:

Typically used in two-stage systems. Reduces tank pressure to an intermediate level for further regulation.

Common for residential systems. Reduces pressure from a 1st stage regulator to a level appropriate for appliances.

Ideal for smaller installations. Combines the functionality of both 1st and 2nd stage regulators into one unit.

Often used with burners, fryers, or equipment requiring high BTU output. Deliver high-pressure gas for industrial or specialized applications.

Designed for systems with multiple tanks. Automatically switches to a reserve cylinder when the primary cylinder is empty.

Ideal for installations with limited space. Reliable pressure control in a small, streamlined package.

Assess Your System’s Requirements

Selecting the correct regulator depends upon the unique demands of a system:

BTU Load

Calculate the total BTU load of all appliances (and any potential future

additions) to ensure that the regulator(s) are adequate for the demand.

Inlet and Outlet Pressure

Verify that the regulator pressure setting matches the system requirements.

Distance from the Tank

Longer distances may require greater inlet pressure or specific types of regulators

to maintain performance.

Environmental Factors

Consider the operating environment, such as extreme temperatures or exposure

to moisture, which can impact regulator performance.

Prioritize Safety and Compliance

Ensure the regulator complies with all relevant safety standards and certifications, such as those established by NFPA (National Fire Protection Association), and your local authority having jurisdiction (e.g. Fire Marshal). Compliance ensures that the regulator is manufactured and tested to safely withstand various operational stresses. Additionally, you should regularly inspect and maintain regulators to avoid potential leaks, clogs, or malfunctions. This includes checking for wear & tear on components, ensuring proper connections, and replacing components (as needed). A proactive approach to maintenance can prevent system failures and extend the life of your equipment, ultimately contributing to safer and more reliable operation.

Stock Up on Quality RegO Regulators

We proudly offer a wide array of RegO regulators that are made in the USA because they’re renowned for exceptional quality and have a long-standing reputation for reliability. RegO regulators are manufactured to meet the highest industry standards, ensuring safe and consistent performance for residential, commercial, and industrial applications. Visit our store or contact us to learn more about how these premium regulators can meet your specific needs. If you’re unsure about the best regulator for your system, consulting an expert is always a smart choice. At LPG & NH3 Supply, our knowledgeable team can help you find the right regulator to suit your specific needs.

CAUTION: The above information is intended for general guidance only and should not be considered as professional or legal advice. Always consult a qualified expert or regulatory authority having jurisdiction for specific advice related to your LP gas system and ensure compliance with all local and national safety regulations. You may also consult the LP-Gas Serviceman’s Manual for additional guidance/information.

Interested in saving this article?

The Case for Propane Autogas:

Why You Should Consider a Propane Conversion System for Your Vehicle or Fleet

A Brief History of Autogas

Propane Autogas has been a viable alternative fuel for more than a century. First discovered in 1910 by Dr. Walter Snelling, propane quickly became a valuable energy source due to its portability and efficiency. By the mid-20th century, Autogas—propane used as a motor fuel—had gained traction, particularly in Europe, where it was widely adopted for taxis, buses, and commercial fleets. Over time, Autogas gained recognition as a cleaner-burning alternative to gasoline and diesel, leading to its classification as a clean fuel under the Clean Air Act Amendments of 1990.

Why Convert Your Vehicle to Propane Autogas?

If you're searching for a propane conversion system, you're likely interested in the benefits of switching to propane Autogas. Autogas presents a compelling case for fleet owners, businesses, and individual vehicle owners looking to reduce fuel costs, improve efficiency, and exhaust cleaner emissions. Its benefits are rooted in three key areas: supply chain stability, cost-effectiveness, and fueling flexibility.

An Abundant and Stable Supply Chain

Propane is a byproduct of both natural gas processing and petroleum refining, making it a readily available fuel source. The United States is one of the world’s largest producers of propane, with a strong and stable supply chain that reduces dependence on foreign energy sources. Unlike other alternative fuels that face production bottlenecks, propane’s well-established infrastructure ensures consistent availability for Autogas users.

Additionally, in less than a decade and a half, the United States has become the world's largest propane exporter. In 2024, the United States averaged 1,757,000 barrels per day (bpd) of propane exports. Most of the exports are waterborne. There are now ships capable of loading over 500,000 barrels of propane in a single cargo.

Cost Savings and Price Stability

One of the biggest advantages of Autogas is its consistently lower price compared to gasoline and diesel. Historically, propane costs 30-50% less per gallon than gasoline, and because it’s domestically produced, it’s less susceptible to volatile global oil price fluctuations. Fleet operators and individuals who switch to Autogas using a propane conversion system benefit from long-term fuel savings and predictable costs, allowing for better budgeting and financial planning.

Key Benefits of a Propane Conversion System

1. Extended Driving Range with Bi-Fuel Systems

One of the primary concerns with alternative fuels is range anxiety. Propane Autogas solves this with bi-fuel systems. Vehicles equipped with these systems can seamlessly switch between

propane and gasoline, effectively doubling their driving range. This ensures that drivers never get stranded due to a lack of Autogas refueling stations and can still take advantage of propane’s cost savings when available.

2. On-Site Fueling with an Autogas Dispenser

Fleet operators who invest in or are provided with an on-site Autogas dispenser enjoy significant logistical advantages. Unlike gasoline and diesel, which require trips to public refueling stations, fleets running on propane can be refueled at their own facilities. This reduces downtime, increases operational efficiency, and allows for bulk purchasing at even lower prices. Additionally, on-site refueling eliminates the uncertainty of finding a nearby Autogas station while on the road.

3. Addressing the Infrastructure Challenge

There are more than 3,400 public propane refueling stations in the United States, according to the National Renewable Energy Laboratory (NREL) and infrastructure continues to grow. Many companies partner with fuel providers to establish private refueling networks, ensuring access to propane when needed. Additionally, bi-fuel vehicles mitigate this concern by allowing drivers to switch to gasoline when an Autogas station is unavailable. With more investment in alternative fuel infrastructure and a growing number of fleet operators adopting propane, Autogas availability will continue to expand in the coming years.

Ready to Upgrade Your Vehicle to Operate Using Propane Autogas?

When modifying your vehicle by adding a propane system, it’s crucial to have the installation done by trained and certified professionals rather than attempting a DIY approach. A propane conversion system involves integrating a high-pressure fuel system, which requires specialized knowledge, tools, and safety precautions. Improper installation can lead to performance issues, safety hazards, and non-compliance with emissions regulations.

Choosing a reputable provider like LPG & NH3 Supply ensures that your propane system meets all safety and environmental standards. Their certified technicians have the expertise to install and calibrate the system correctly, optimizing performance while ensuring compliance with EPA regulations. A professional installation also guarantees long-term reliability, reducing the risk of costly repairs or system failures down the road.

Conclusion

Propane Autogas is a proven, reliable, and cost-effective alternative fuel with a well-established supply chain, lower fuel costs, and significant operational advantages. Whether you're a fleet operator or an individual looking to reduce fuel expenses, a propane conversion system can

help you unlock the benefits of Autogas. Its ability to power bi-fuel vehicles, support on-site refueling, and reduce emissions makes it an excellent choice for those seeking a cleaner, more economical fuel solution. The industry’s ongoing growth and technological advancements ensure that Autogas will continue to play a key role in the transition to cleaner transportation solutions.

Interested in saving this article?